Iphrojekthi yokuhlunga ngokuzenzakalelayo yamathayi aqediwe e-Shengshitailai Rubber ibona ikhono lokuzishintsha kanye nokulandela ulwazi lokuhamba, ukuhlunga, ukufakwa kwamaphalethi, ukugcinwa nokulethwa, kanye nokwenza ngcono ngokuqondile ukusebenza kahle kanye nokunciphisa izindleko zokusebenza kwamabhizinisi.

Ukuze uvumelane nokuthuthukiswa kwamabhizinisi kanye nesidingo semakethe, kanye nokwenza ngcono ukusebenza kahle kokukhiqiza nokunciphisa izindleko zabasebenzi, ngo-2015 iQingzhou Shengshi tailai Rubber Company (lapha ngemva kokubizwa ngokuthi "iSheng Tai") yanquma ukukhiqizwa kwamasethi ayizigidi ezingu-12. ukuhlunga okuzenzakalelayo kwesondo okuqediwe, ngokusebenzisa ukwenziwa ngcono okuqhubekayo kanye nephrojekthi yokubonisa ngesigamu sonyaka, okokugcina kuqinisekisa isixazululo sokulethwa okuphelele kokugcinwa kwamasondo okuphelile kanye nokuhlanganiswa kwesistimu yokuhlunga.

Shengshi Tailai Rubber

Isistimu yokuhlunga ezenzakalelayo yamathayi aphelile

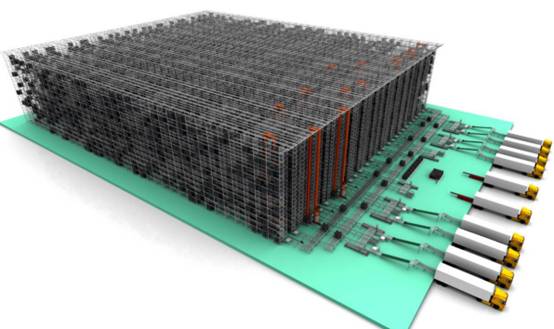

Iphrojekthi yokuhlunga ezenzakalelayo ihlanganisa indawo engamamitha-skwele angaba ngu-21000, ukutshalwa kwezimali okuphelele mayelana nezigidi ezingu-200 zama-RMB, iphrojekthi yokuhlunga ye-Shengtai ngokuyinhloko iqukethe ukudlulisa okuzenzakalelayo okuhlakaniphile, ukuhlunga, ukupakisha okuzenzakalelayo, uhlelo lokugcina oluzenzakalelayo ngemva kokutholwa.Ngaphansi kokugcwaliseka kwesistimu yolwazi ye-ERP ezishintshayo, inqubo ehlakaniphile nengenamuntu, ukukhishwa konyaka kwamasethi ayizigidi ezingu-12 zamathayi kuhlangabezana nesidingo nokuthuthukiswa kwe-Shengtai yesikhathi eside.

Uhlelo lusebenzisa i-rack ehlanganisiwe yokugcina, isamba semigudu eyi-14, i-14 ibeka ngaphezu kwamamitha angu-30 we-stacker, iqoqo elikhulu kunawo wonke lama-pallets angu-50400.Umkhiqizo uthuthwa uyiswe endaweni yokugcina impahla esitezi sesibili, ngohlelo lokuskena lwe-panoramic lwemikhiqizo efanelekayo kanye nemikhiqizo engafanelekile ukuze ihlungwe ngokuzenzakalelayo, bese kuba irobhothi elizenzakalelayo lokunamathisela i-palletizing ukuze ligcinwe ngezintambo zokudlulisela ezithunyelwa endaweni yokugcina ngamasethi angu-14 omshini wokupakisha, esitezi sokuqala. wesondo eliqediwe ngomshini we-chain roller, i-telescopic belt conveyor kanye nezinye izinto zokuthutha ukuze kuqedelwe ukulethwa.

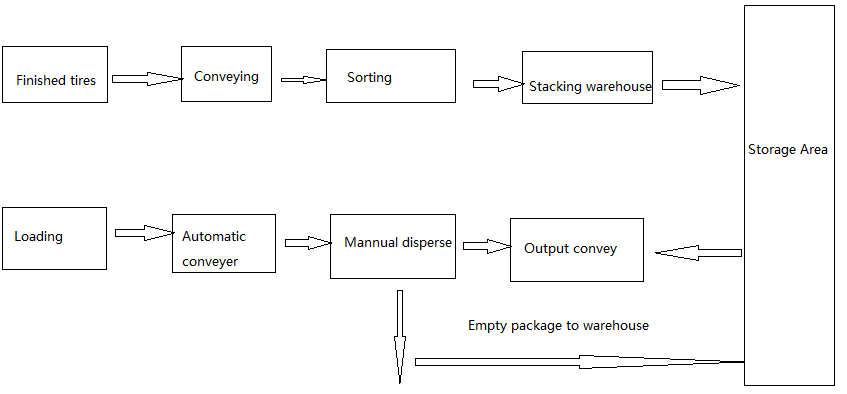

Ishadi lenqubo yonke yephrojekthi

1. Ukugcina imikhiqizo eqediwe endaweni yokugcina impahla

Isondo eliqediwe le-workshop lihlolwe umshini wokuhlola onamandla.Uma kudlula ukuhlolwa, kuthuthelwa endaweni yokuhlunga esitezi sesibili sendlu yesitolo esime mpo ngephaseji.Amathayi akhubazekile alethwa endaweni yokulungisa.Amathayi afanelekile ngemva kokulungiswa aphinde ahambe kulayini emhubheni aye endaweni yokuhlela yaphansi.

Umugqa wokuhlunga ku-2ndindawo yokuhlela yaphansi ihlelwa ngokuya ngokucaciswa kwamachweba okuhlunga angu-12, futhi irobhothi laseLongmen lilayisha ngokuzenzakalelayo amathayi endaweni eqokiwe yedeski elihambayo lokugcina.Lapho isondo elilodwa linqwabelana phezu kwesitaki endaweni yokugcina izinto ezihambayo, irobhothi laseLongmen lithwala sonke inqwaba yamathayi liyise endaweni eqokiwe emtatsheni wezincwadi waseLongmen.Ngokuhambisana nomyalelo wedatha ye-WMS, irobhothi laseLongmen lathwala isitaki samasondo esihambisana nenombolo yesitaki lisiyisa ethreyini engenalutho.Ngemva kwesitsha sethreyi yesitoreji se-RGV esithuthelwe kukhompuyutha eshiwo, ukuphatha isitaki eshalofini lezimpahla ezikhethiwe.

A: Ukuhlunga ukuphatha okungavamile: umshini wokuhlunga ufakwe i-overout outlet engavamile, futhi isondo eliqediwe lifakwa embotsheni yokuphatha engavamile ngemanuwali bese ligcinwa endaweni yokugcina impahla.

B: enqubweni yokugcina isitaki yokutholwa kokubukeka kanye nokubuyekezwa kwekhodi yebha, njengesimo esingavamile, ukubamba okuzenzakalelayo endaweni yokubamba okungavamile, ukucubungula ngesandla, kanye nokugcinwa kwempahla.

2. Impahla eqediwe Ex- warehouse

Ngemuva kokuthi i-WMS ithumele imiyalelo yokuthumela, i-othomathikhi ye-tray stacker beka izimpahla emshinini wokuthutha, bese ulayini wokuthutha we-annular uthumela izimpahla ethekwini lokudiliva elihambisanayo, ngepuleti lokwenziwa, ilebula, isidluliseli sebhande, isondo elimile, isidluliseli sebhande le-telescopic sithuthwa iloli ukuze zilethwe.

Ukucubungula i-pallet engenalutho: ithreyi yamathayi eqediwe ngemuva kokuhlukana ne-pallet, abasebenzi bazothumela mathupha endaweni yokugcina okuzenzakalelayo

Kulo lonke uhlelo lokulandelela ulwazi lwesondo ngalinye, isitoreji kanye nolwazi kungaba ekulawuleni okuzenzakalelayo okugcwele, ukugwema amaphutha okwenziwa abangelwa amaphutha okugcina nokulethwa, ukuqaliswa okusebenzayo kokulandelelwa kolwazi, ukonga izindleko eziningi zokusebenza kwamabhizinisi, futhi ngcono ukusebenza kahle kwe-theoperation.

Isikhathi sokuthumela: Sep-02-2022